Roofing underlayment types include felt, synthetic, and rubberized asphalt variants. Each serves as a protective layer between the roof deck and shingles.

Choosing the right roofing underlayment is crucial for any roofing project. It acts as a secondary barrier against water infiltration, protecting your home from leaks and structural damage. Homeowners and contractors must understand the different types available to make informed decisions for their projects.

With advancements in materials and technology, the range of underlayment products has expanded, offering improved durability, installation ease, and compatibility with various roofing materials. This guide will provide you with an essential overview of the types of roofing underlayment, helping you select the best option for longevity and performance of your roofing system. By investing time in understanding these options, you can ensure your roof is well-equipped to withstand the elements while enhancing its overall lifespan.

Credit: www.roof-crafters.com

Roofing Underlayment Essentials

Welcome to the ‘Roofing Underlayment Essentials’ section of our comprehensive guide to roofing. At the heart of any resilient roofing system, the underlayment remains a crucial component often hidden from sight, yet vitally important in protecting your home from the elements. This underlayer serves as a silent shield, preventing water penetration and providing an extra layer of insulation for your rooftop. Whether you’re constructing a new roof or replacing an old one, understanding the role and importance of roofing underlayment is key to a durable and long-lasting roof.

Importance In Roofing Structure

The underlayment of a roof is more than just an accessory; it’s the foundational barrier that stands between your home and nature’s forces. This component is critical for various reasons:

- Protection Against Water: During heavy rain or snow, the underlayment functions as the last line of defense against water infiltration that might bypass the shingles.

- Weatherproofing: It helps safeguard your home against wind-driven rain and ice dams, which can cause significant damage.

- Increased Lifespan: By preventing leaks, it extends the life of your roof decking and, consequently, your entire roofing system.

- Added Insulation: Roofing underlayment can also provide extra thermal insulation, contributing to more stable indoor temperatures.

Description Of Underlayment Purpose

The primary purpose of roofing underlayment lies in its multifunctional capabilities:

| Function | Benefit |

|---|---|

| Moisture Barrier | Prevents water from reaching the roof deck |

| Vapor Barrier | Reduces the risk of condensation and mold growth |

| Temporary Protection | Acts as a safeguard during construction when the top layer isn’t completed |

| Protective Layer | Buffers the roof deck from the potential damage caused by shingle installation |

Choosing the right underlayment is essential as it carries out duties that ensure the longevity and effectiveness of your roofing structure. A quality underlayment not only prevents distress from weather challenges but also enhances the overall performance of the roof. For homeowners seeking to maximize their roofing investment, an understanding of this elemental layer is indispensable.

Types Of Roofing Underlayment

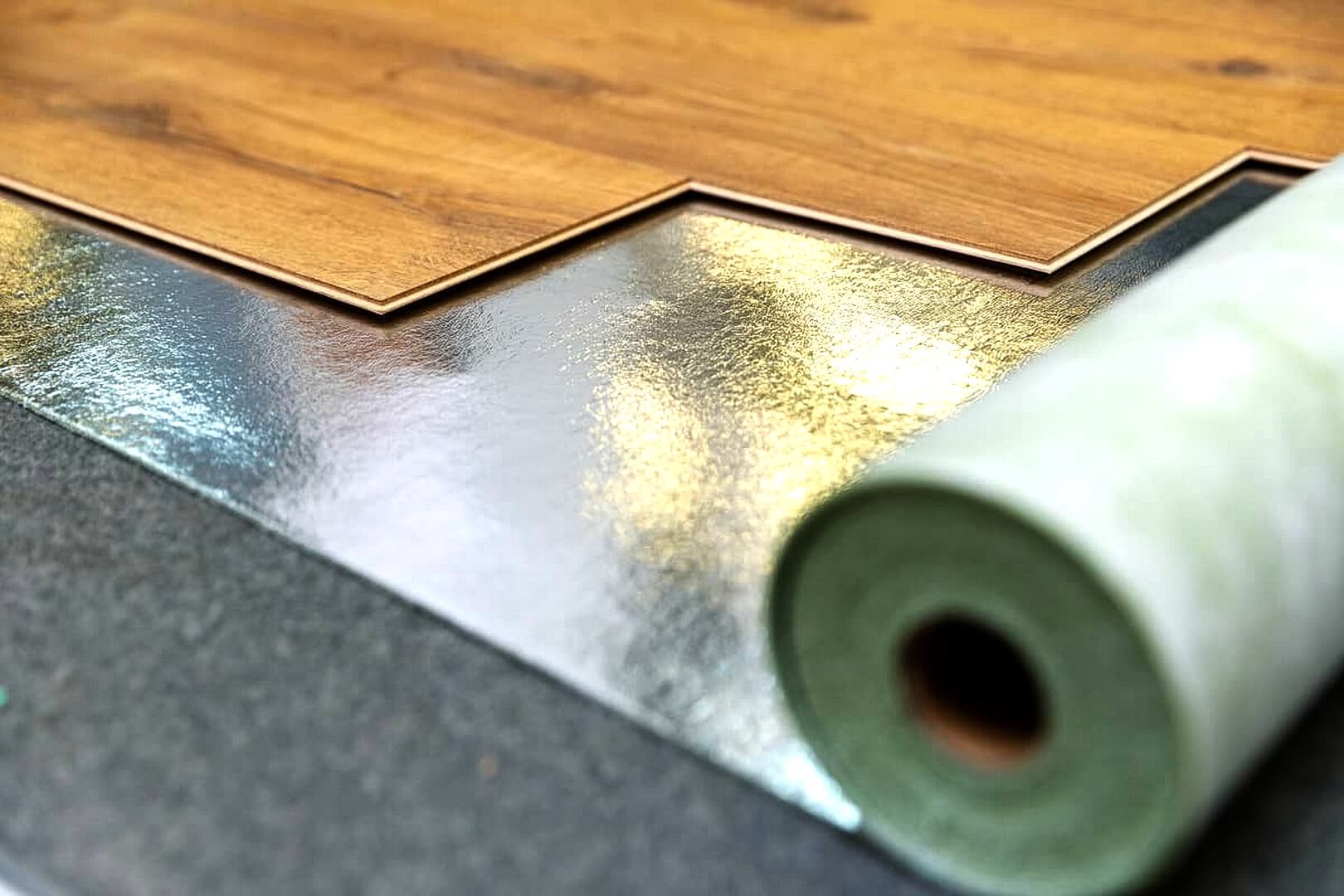

Selecting the right roofing underlayment is a critical step in any roofing project. This layer, hidden beneath the shingles or other roofing material, serves as an additional barrier against moisture and the elements, protecting the roof deck from damage. Different types of underlayment offer varied levels of protection, durability, and price points to suit diverse roofing needs. Let’s delve into the three primary underlayment options available.

Asphalt-saturated Felt

Asphalt-saturated felt underlayment, commonly known as felt paper, has been a staple in roofing for decades. Typically made from a blend of organic or fiberglass substrate and asphalt, this type of underlayment comes in two standard weights: 15-pound and 30-pound felt. The 30-pound variety offers more substantial protection and durability than its lighter counterpart.

- Cost-effective: An excellent choice for those on a budget without sacrificing quality.

- Water-resistant: Offers a basic level of moisture protection.

- Variety: Available in different thicknesses to suit specific roofing requirements.

Non-bitumen Synthetic Underlayment

Synthetic underlayment, made from polypropylene, polyester, or polyethylene, is a more recent innovation in the roofing industry. This high-tech alternative to traditional felt offers several benefits:

| Feature | Benefit |

|---|---|

| Lightweight: | Easier to handle and install, leading to quicker roofing jobs. |

| Durability: | Resistant to tears and punctures, which can improve roof longevity. |

| Moisture resistance: | Excellent protection against water and moisture buildup. |

Rubberized Asphalt Underlayment

Rubberized asphalt underlayment is the premium choice for homeowners seeking the highest level of protection. This self-adhering underlayment creates a watertight seal around nails and offers:

- Superior waterproofing: Ideal for areas with heavy rain or snow.

- Sound-dampening qualities: Helps to reduce external noise.

- Flexibility: Adapts to the contours of the roof deck for a snug fit.

Although more costly, the advanced properties of rubberized asphalt underlayment may result in long-term savings by reducing maintenance and extending the roof’s lifespan.

Selecting The Right Underlayment

Selecting the right underlayment for your roofing project is not just a choice, but a necessity. It’s the unsung hero of your roof’s defense system, lying beneath the shingles, tiles, or metal safeguarding your home from the elements. To understand how to choose the best underlayment, various factors must be considered.

Factors Influencing Underlayment Choice

Your selection should be informed by the roofing material to be installed, the roof pitch, and even the local building codes. Furthermore, aspects such as durability, water-resistance, and ease of installation should also shape your decision. Here’s a concise breakdown:

- Compatibility with Roofing Material: Some underlayments are specifically designed for use with particular roofing materials.

- Pitch of the Roof: Steeper slopes require different types of underlayment than low-slope roofs.

- Building Codes: Ensure compliance with local regulations which can dictate underlayment specifications.

- Longevity: Opt for underlayment that can match the lifespan of your roofing material.

- Installation: Consider the ease of installation as this can impact the overall cost.

Climate And Environmental Considerations

The climate you live in plays a pivotal role in determining the appropriate underlayment. The cold and snowy North demands an underlayment that can withstand heavy snow loads and ice damming, while the hot and humid South will benefit from an underlayment that combats moisture and heat efficiently.

| Climate | Recommended Underlayment |

|---|---|

| Cold/Icy Regions | Synthetic underlayment with good thermal resistance |

| Wet/Moist Climates | Rubberized asphalt underlayment for superior seal |

| High Wind Areas | Reinforced underlayment that resists tearing |

| High-Temperature Zones | Reflective underlayments to reduce heat intake |

Moreover, consider the environmental factors such as proximity to coastal areas where salt spray could be an issue or areas susceptible to wildfires, where a fire-resistant underlayment would be essential.

A Comprehensive Guide To Roofing Underlayment Types

Roofing underlayment is a crucial component of any roofing system. It acts as a protective barrier, safeguarding your home from the elements and enhancing the durability of your roof. Understanding the various types of underlayment and their unique properties is essential for both homeowners and professionals in the industry. This guide provides an in-depth look into the world of roofing underlayments, helping you make an informed choice tailored to your specific roofing needs.

Comparing Performance And Longevity

Different types of roofing underlayment offer varied levels of performance and longevity. It’s important to consider how these factors align with the climate conditions your roof will face and the lifespan you expect from your roofing materials.

| Type of Underlayment | Performance | Longevity |

|---|---|---|

| Asphalt-saturated felt | Good water resistance | 15-30 years |

| Rubberized asphalt | Excellent waterproofing and adhesive properties | 25+ years |

| Synthetic | High strength, tear resistance, and UV protection | 40+ years |

Factors such as UV exposure, temperature fluctuations, and physical wear greatly influence the performance over time. Selecting an underlayment with a proven track record for outstanding performance and extended longevity will ensure your roof stands the test of time.

Suitability For Different Roofing Materials

Roofing materials react differently to various underlayment types. Identifying the right combination is key to a functioning and long-lasting roof system.

- Asphalt shingles work well with nearly all types of underlayment, with asphalt-saturated felt being the traditional choice.

- Metal roofing pairs best with synthetic underlayment for its temperature-resistant properties and durability against the metal’s expansion and contraction.

- Clay and concrete tiles benefit from using highly breathable underlayment options like synthetic materials to manage moisture.

It is critical to match your roofing material to a compatible underlayment to prevent material degradation and enhance the overall performance of your roof. Selecting a suitable underlayment can also extend the life expectancy of the primary roofing material, providing additional value to any roofing project.

Installation Techniques For Underlayment

Roofing underlayment is a critical barrier that stands between your roofing material and the roof deck. It serves as a secondary layer of defense against the elements, helping to ensure that your home remains secure and dry. Understanding and applying the correct installation techniques for underlayment are as important as choosing the right type of underlayment. Proper installation prevents leaks, extends the life of your roof, and maintains your warranty coverage.

Basic Steps For Proper Installation

The way you install roofing underlayment can significantly impact the longevity and effectiveness of your roof. Follow these basic steps to ensure a proper installation:

- Prepare the Roof Deck: Clean the deck of any debris or protruding nails that may tear the underlayment. A smooth surface promotes better adhesion.

- Roll Out the First Course: Start from the edge of the roof and roll out the underlayment horizontally, parallel to the eaves.

- Fasten the Underlayment: Use roofing nails or staples to secure the underlayment to the decking, following the manufacturer’s recommendations on spacing.

- Ensure Proper Overlap: Each horizontal course should overlap the one below it by at least two inches, and each vertical course should have a four-inch overlap to prevent water ingress.

- Cover Entire Roof: Continue laying courses with appropriate overlap until the entire roof is covered, ensuring that the underlayment lies flat and is properly sealed at the hips and valleys.

- Seal Seams: Depending on the underlayment type, you may need to seal seams with roofing cement or a specialized tape to achieve a watertight bond.

- Inspect the Installation: Double-check for any loose areas, and make sure vents and chimneys are properly sealed and flashed.

Common Pitfalls And How To Avoid Them

Mistakes during the installation of roofing underlayment can compromise a roof’s integrity. Here are some typical pitfalls and tips to avoid them:

- Incorrect Overlap: Always adhere to the manufacturer’s instructions for overlapping courses. Not overlapping enough can lead to leaks.

- Wrinkles and Bubbles: Ensure the underlayment is as flat as possible during installation. Prevent wrinkles by rolling out the material smoothly and tautly.

- Ideal Conditions: Try to install underlayment in mild weather conditions. Extreme temperatures can affect the flexibility of the material.

- Proper Fastening: Using too few fasteners can cause the underlayment to lift or flap, while too many can create tears or punctures. Follow the correct fastening pattern.

- Tearing at the Eaves: To prevent tears due to wind uplift, ensure that the underlayment extends slightly over the edge of the eaves and is adequately secured.

- Bypassing Flashing: Always install flashing around roof penetrations like chimneys, vents, and roof-to-wall intersections to prevent water infiltration.

Ensuring Optimal Underlayment Longevity

Your roofing underlayment plays a critical role in protecting your home from the elements. While sturdy and designed to last, it still requires care to maintain its integrity over time. Achieving optimal underlayment longevity is not just about installing the right material; it’s about understanding how to maintain it and recognizing when it’s time for replacement.

Maintenance Tips For Different Types

Maintaining your roofing underlayment depends on the type you have. Here are key maintenance tips for the most common types:

- Asphalt-saturated felt: Keep foot traffic to a minimum to avoid damage. Inspect for moisture and ensure proper attic ventilation to prevent saturation and deterioration.

- Synthetic underlayment: Regularly check for tears or punctures. Though durable, synthetic materials can also be vulnerable to sharp objects or high winds.

- Rubberized asphalt: Due to its self-healing properties, little maintenance is needed. Periodic inspections will suffice to ensure no areas have been compromised.

Maintenance also includes keeping the roof surface clean from debris and trimming overhanging tree limbs that could potentially damage the underlayment.

Signs That Indicate The Need For Replacement

Over time, several signs might indicate that your roofing underlayment needs replacing:

| Type | Signs of Replacement Need |

|---|---|

| Asphalt-saturated felt | Brittle or torn material, water stains in the attic, or a sagging roof deck. |

| Synthetic | Noticeable rips, degraded UV protection, or detachment from staples or nails due to wind uplift. |

| Rubberized asphalt | Visible cracks, adhesion loss at the seams, or penetration from foreign objects. |

Keep an eye out for these issues, especially after severe weather events. A proactive approach will protect your home from water damage and avoid more costly repairs in the future. Regular professional inspections can also help extend the life of your underlayment by identifying and addressing potential problems early.

Frequently Asked Questions Of A Comprehensive Guide To Roofing Underlayment Types

What Is Roofing Underlayment?

Roofing underlayment is a barrier installed between the roof deck and shingles. It acts as protection against water penetration and improves roof durability. Often made from felt or synthetic materials, it’s vital for roof longevity.

Why Use Synthetic Underlayment Over Felt?

Synthetic underlayment offers superior durability, resistance to water and UV light, and is lighter. It’s also safer for workers during installation. Due to these benefits, many choose synthetic over traditional felt underlayment.

Which Underlayment Is Best For Metal Roofs?

For metal roofs, a synthetic underlayment is typically recommended. It should have high-temperature resistance and provide a strong barrier against moisture. This minimizes the risk of condensation that metal roofs can experience.

How Often Should Underlayment Be Replaced?

Underlayment should be checked when replacing shingles or tiles. If it’s damaged or deteriorated, replace it to ensure the roof’s integrity. Usually, it lasts as long as the roofing material it’s paired with.

Conclusion

Selecting the right roofing underlayment is crucial for any home. It safeguards against moisture, enhances durability, and can even boost your roof’s overall performance. Remember, the choice you make intertwines with longevity and protection. Thoroughly evaluate your options, consult a professional, and invest wisely in your home’s defense against the elements.

Choose wisely; your roof’s integrity depends on it.